LTD URAL FOREST

About us

Ural Timber Company (formerly Serov Energosokombinat) is a manufacturer of wooden transmission line poles and communication lines made of high-quality timber from the Urals. The company, founded in 1959, was the largest producer of poles in the structure of the Ministry of Energy of the USSR with a production volume of 150 thousand/m³ power transmission line poles per year. In addition to its main products, the Serov Power and Timber Plant was the largest supplier of carpentry products. Translated with www.DeepL.com/Translator (free version)

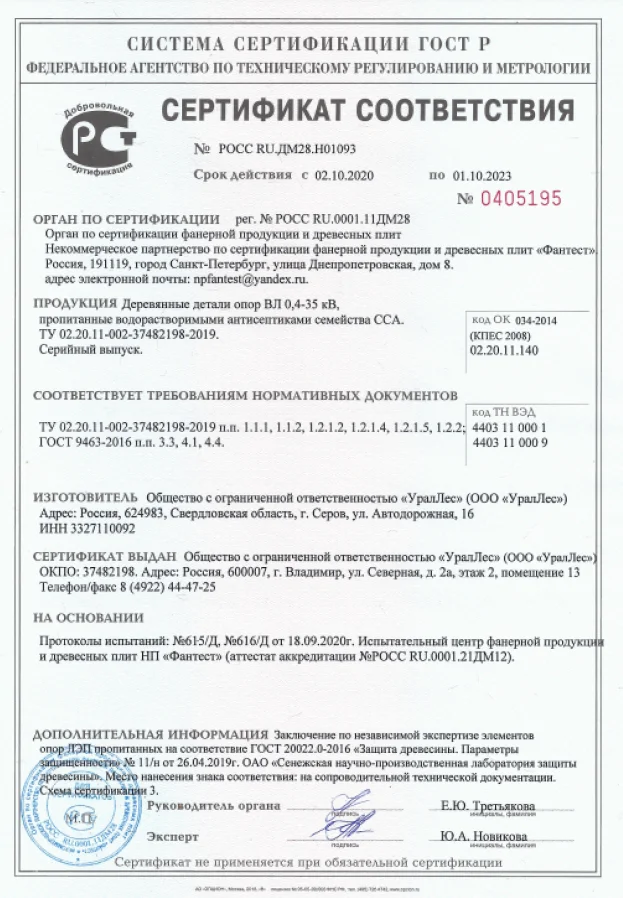

Pine growing above 60 degrees north latitude is used for the production of the supports, which guarantees the high quality of the finished products. The products are certified by the Senezh Scientific and Production Wood Protection Laboratory.

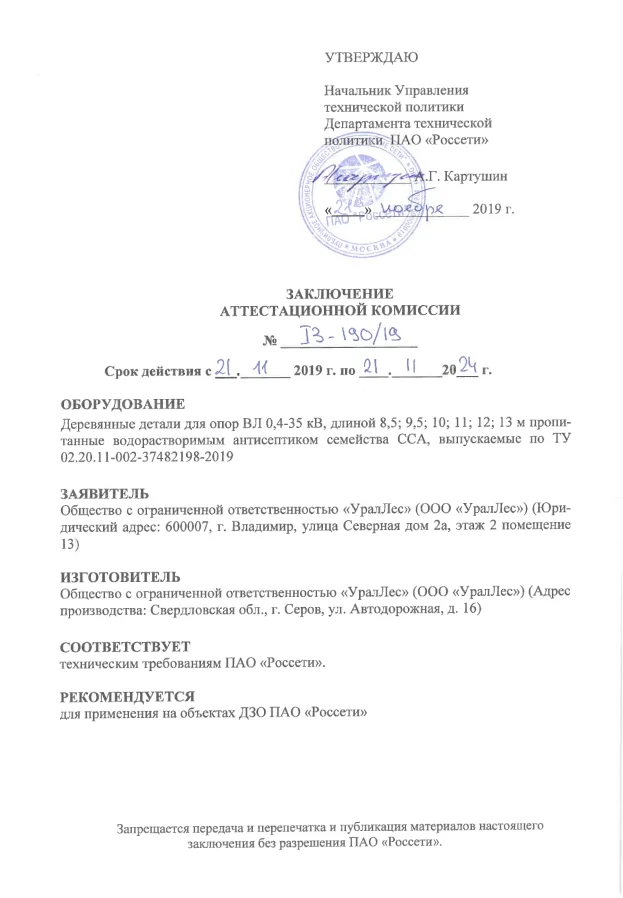

Production is organised in accordance with the standards of the Russian Federation for the domestic market and in accordance with the requirements of the international standard BS 1990-1:1984. Our supports are recommended for use at Rosseti's facilities.

The company currently produces two types of finished products:

- wooden transmission line poles in lengths from 6 to 13 metres, class L, M, S. The supports comply with the standards of the Russian Federation for the domestic market and the requirements of the international standard BS 1990-1:1984.

- sawmill products: sawn timber, planed mouldings.

Pine grown above 60 degrees north latitude is used for the production of the poles, which guarantees the high quality of the finished products.

The location of the company allows for shipment of finished products by all means of transport:

- by road transport.

- by rail from the company's premises (own railway sidings).

- river vessels - sea through the port of Perm, with a tonnage of 3 to 5,000 tonnes.

LTD URAL FOREST

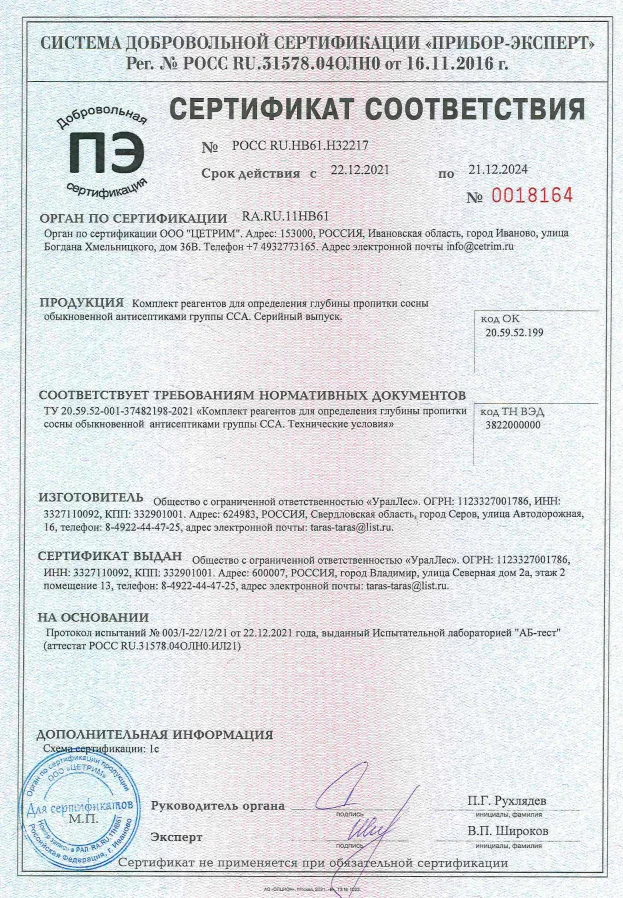

Company certificates

TECHNOLOGY

PRODUCTION TECHNOLOGY DESCRIPTION

Raw materials for the manufacture of wooden poles components: | Pine of common 1st and 2nd grade according to GOST 9463-2016, harvested in the northern regions of Russia. |

Impregnation process: | in a high-pressure autoclave using the VDV (vacuum-pressure-vacuum) method. |

Impregnation compound: | water-soluble antiseptic of the CCA family |

Depth of penetration of the antiseptic: | 85% - 100% of the sapwood layer width according to GOST 20022.0-2016 |

The amount of wood preservative contained in the wood: | not less than 11 kg per m³. of wood |

Marking: | The supports are labelled with labels indicating the manufacturer, length, support class, type of preservative, year of manufacture and batch number. |

Service life in contact with the soil: | at least 50 years from the date of installation. |

Factory warranty: | 10 years from delivery |