Production of wooden transmission poles

«UralForest» — is one of the leading plants for the production of 0.4-35kW power transmission line poles and communication lines. High quality products, 10-year warranty

ПРОКЛАДКА сетей МЕТОДОМ ГОРИЗОНТАЛЬНО НАПРАВЛЕННОГО БУРЕНИЯ (ГНБ)

- Highly qualified specialists

- We travel to sites in the Central Federal District

Experience

The factory has been in operation since 1959

Quality

Durable Ural timber

Delivery

By all means of transport anywhere in the Russian Federation and the world

Company production

We produce

Wooden transmission line poles with lengths of 6 to 13 metres in classes L, M, S.

Can make supports to your dimensions from 1 M.

- Northern pine has a density of 500-515 kg/m³. It is perfectly machinable and has a high degree of impregnation.

- Due to its higher resin content, pine is better able to resist the damaging effects of microorganisms: stain, fungi, etc.

- For the manufacture of the timber supports, we only use 1st grade pine trunk pieces, strength class M, MS, harvested in the autumn and winter period.

Quality that has stood the test of time

Ural Forest - a tradition of quality since 1959

Ural Timber Company (formerly Serov Energosokombinat) is a manufacturer of wooden transmission line supports and communication lines made of high-quality timber from the Urals. The company, founded in 1959, was the largest producer of supports within the USSR Ministry of Energy with a production volume of 150,000/m³ of transmission line supports per year.

In addition to its main products, the Serov Energia woodworking plant was the largest supplier of carpentry products.

USSR technology

The production process, which has been fine-tuned over the years, makes it possible to produce products that meet the requirements of GOST. The production capacity of the plant is up to 50,000 m3 of wooden power transmission poles per year.

ISO 9001:2015 standard

The products are certified by the Senezh Research and Production Laboratory for Wood Protection. The quality management system is certified according to ISO 9001:2015

Strict quality control

A multi-stage inspection system at every stage of production - from incoming raw materials to finished products. A regulated process for selecting reliable suppliers.

Well-established logistics

Proximity of highways and railway station, own railway siding, availability of river port in Perm. Delivery of supports to any region of Russia and the world.

OPTIMAL CHOICE

Need wooden transmission poles?

Nordic pine overhead line supports are recommended for use by RAO UES as the best solution for reconstructing obsolete power lines and constructing new ones.

major differences

How are wooden poles more advantageous than their reinforced concrete counterparts?

Economical

Easier to install

Durable

Holds heavy loads

No domino effect

Stable in soils

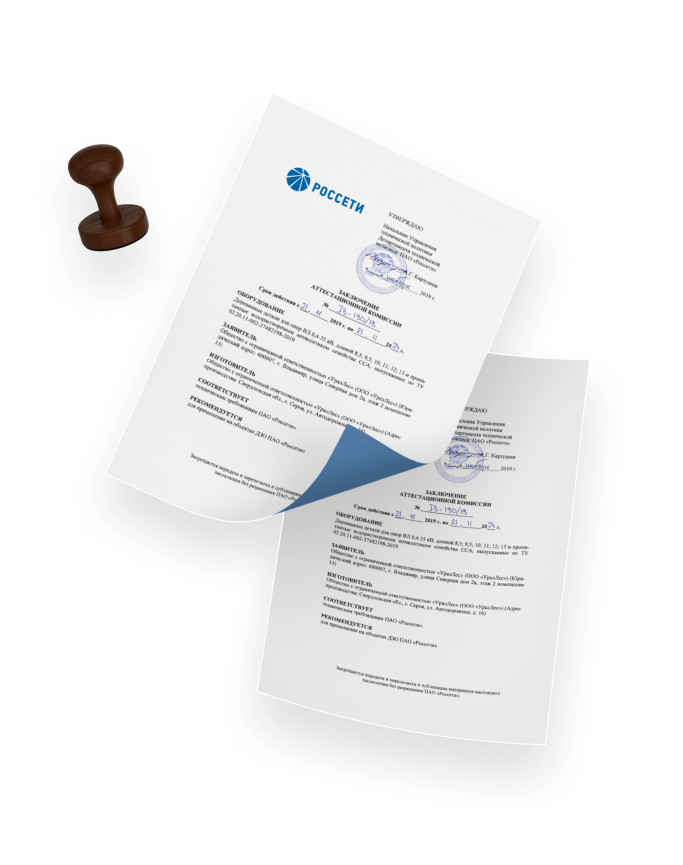

Expert judgement

Our supports are fully compliant with Rosseti's requirements and standards:

GOST 9463-2016 (Round coniferous timber - Technical conditions);

GOST 20022.6-93 ("Wood protection. Impregnation methods");

GOST 20022.0-93 ("Wood protection. Protection parameters");

International Standard BS 1990-1:1984.

TU 02.20.11-001-96502166-2019.

The right technological process step by step

How we produce the poles

We use the time-honoured Soviet production technology to manufacture the supports. The material is northern pine, which has a denser and less porous structure than species growing in the Russian midlands.

Timber harvesting

Debarking and peeling

Wood drying

Impregnation with protective coatings

Binding the antiseptic compound

Antiseptic

Advantage of the antiseptic used

GTC

Strict quality control at all stages of production

1. Checking incoming raw materials

The wood raw material is carefully inspected for rot and cracks.

2. Bend test

A 7-metre support must be able to withstand a load of at least 350H applied at 0.6m from the top (carried out prior to impregnation with antiseptic).

3. determination of the impregnation depth

The impregnation depth is checked with a core sampler. The minimum impregnation depth is at least 85% of the sapwood width. In practice, up to 100% of the sapwood is impregnated. The impregnation process data (temperature, pressure) and the control data obtained shall be recorded as the factory certificate for the given batch of poles.